Cement Tile Design and Production for Beginners

Course final project

A course by user2527370 surname2527370 , Carpenter, Builder, and Teacher

Joined April 2020

Learn the artisanal method for making cement tiles with professional finishes

About the final project for: Cement Tile Design and Production for Beginners

Cement Tile Design and Production for Beginners

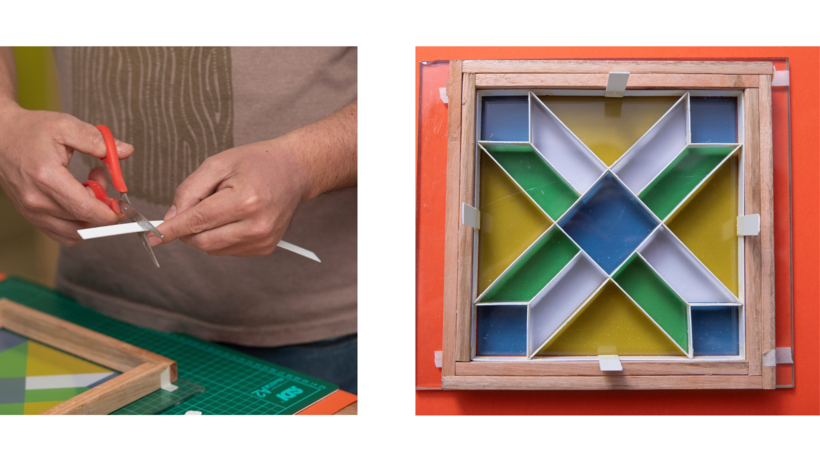

“With joy I have to tell you that we have reached the end of the course. Hope you enjoyed it as much as I did. I confess that since I started preparing the course, I have made it my goal to teach you in the best way, putting sincere and true energy to reflect a real and possible job. It was a lot of work by many people who helped me understand and translate all my knowledge of this incredible technique into video format. The first thing I would like to tell you is ... Thank you for having trusted and being there until the end! I hope you carry out your own project, because I believe that real knowledge is what is passed through the body, translated into the desires of each one. Do not hesitate, start your project! I will accompany you in the forum for whatever you need. Sometimes I will not be able to answer you instantly, but I will answer all the questions. I invite you to also help yourself from all those who are taking this course. Now I share with you the step by step process of creating tiles, so that it is easier for you to remember and follow it. The first thing is to choose the reason, this part is essential because it is the image of what will remain in your project. I recommend that you look at floors, photos, posters, everything you can and make a folder with all those images or you can look at the file that I left you and that serves as inspiration.

Partial transcription of the video

“Final project We're at the end of the course. Thank you for choosing it. I hope you enjoyed it as much as I did. I think it's important for you to now take on your own projects, do lots of things, experiment, try out. The idea of the course is that the floor is something that you like, that appeals to you, that has your colors, your shapes, a floor for boys or girls. It could have a bear, a fruit. If I chose this motif, I know the mold will be harder to make. We can use a 3D printer, we can ask for help if we use fine sheets or molds. All of these decisions are the first to start experiment...”

This transcript is automatically generated, so it may contain mistakes.

Course summary for: Cement Tile Design and Production for Beginners

-

Category

Craft -

Areas

Arts & Crafts, Decoration, DIY, Furniture Design & Making, Interior Design

A course by user2527370 surname2527370

During his time building houses, Juan Rossi learned the importance of materials. They must be strong, but also beautiful. Through a seemingly infinite search, he eventually found the perfect union in hydraulic tiles, thanks to their incredible durability and aesthetic qualities.

For over ten years, he has been teaching classes on how to use cement, specifically for limestone and hydraulic tiles, and how to employ different tiles in different spaces. His work can be discovered on Instagram, as well as through his own courses and products.

- 99% positive reviews (366)

- 11,285 students

- 14 lessons (2h 22m)

- 27 additional resources (15 files)

- Online and at your own pace

- Available on the app

- Audio: Spanish, English

- Spanish · English · Portuguese · German · French · Italian · Polish · Dutch

- Level: Beginner

- Unlimited access forever